Sterile and Efficient Design

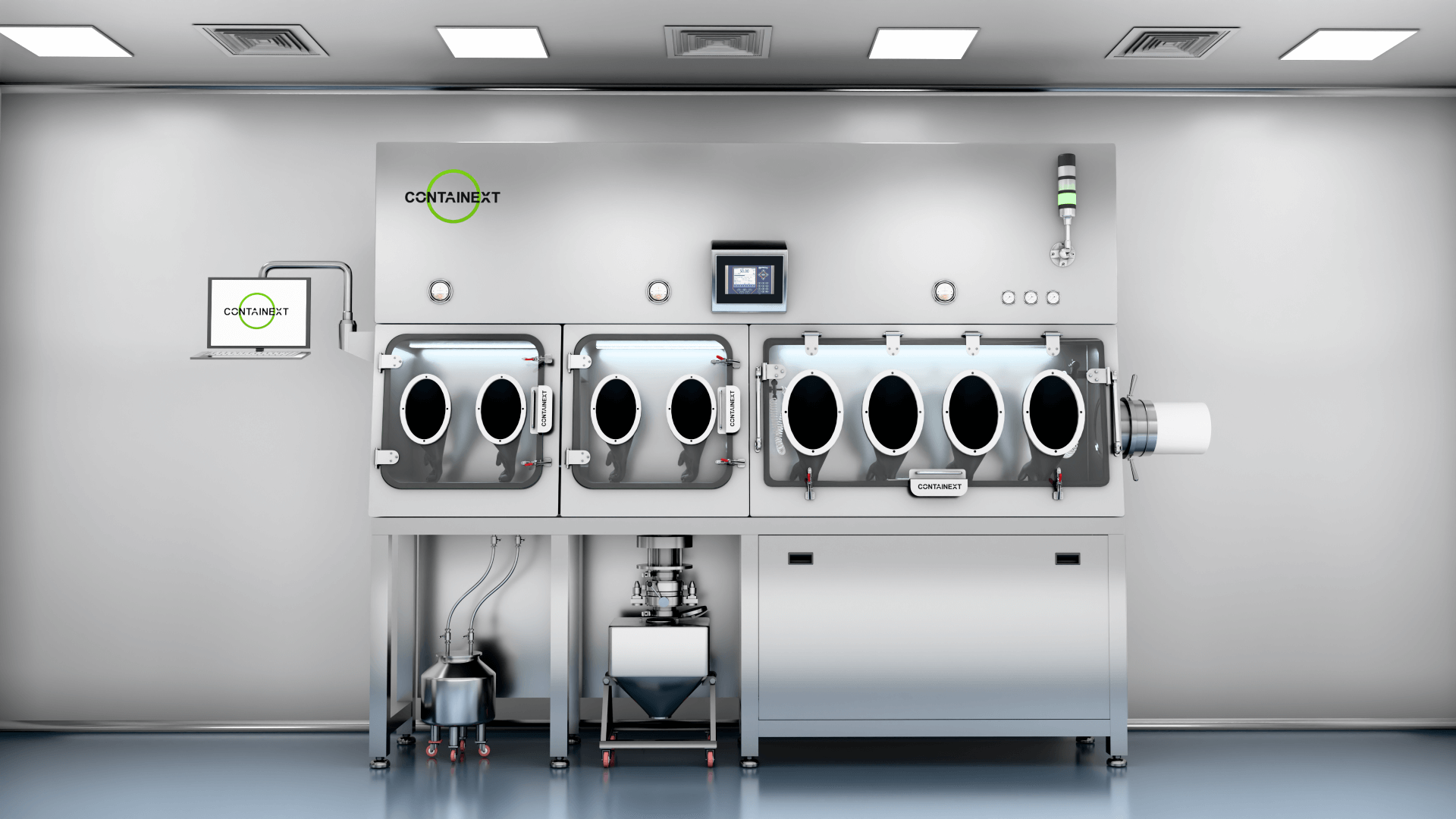

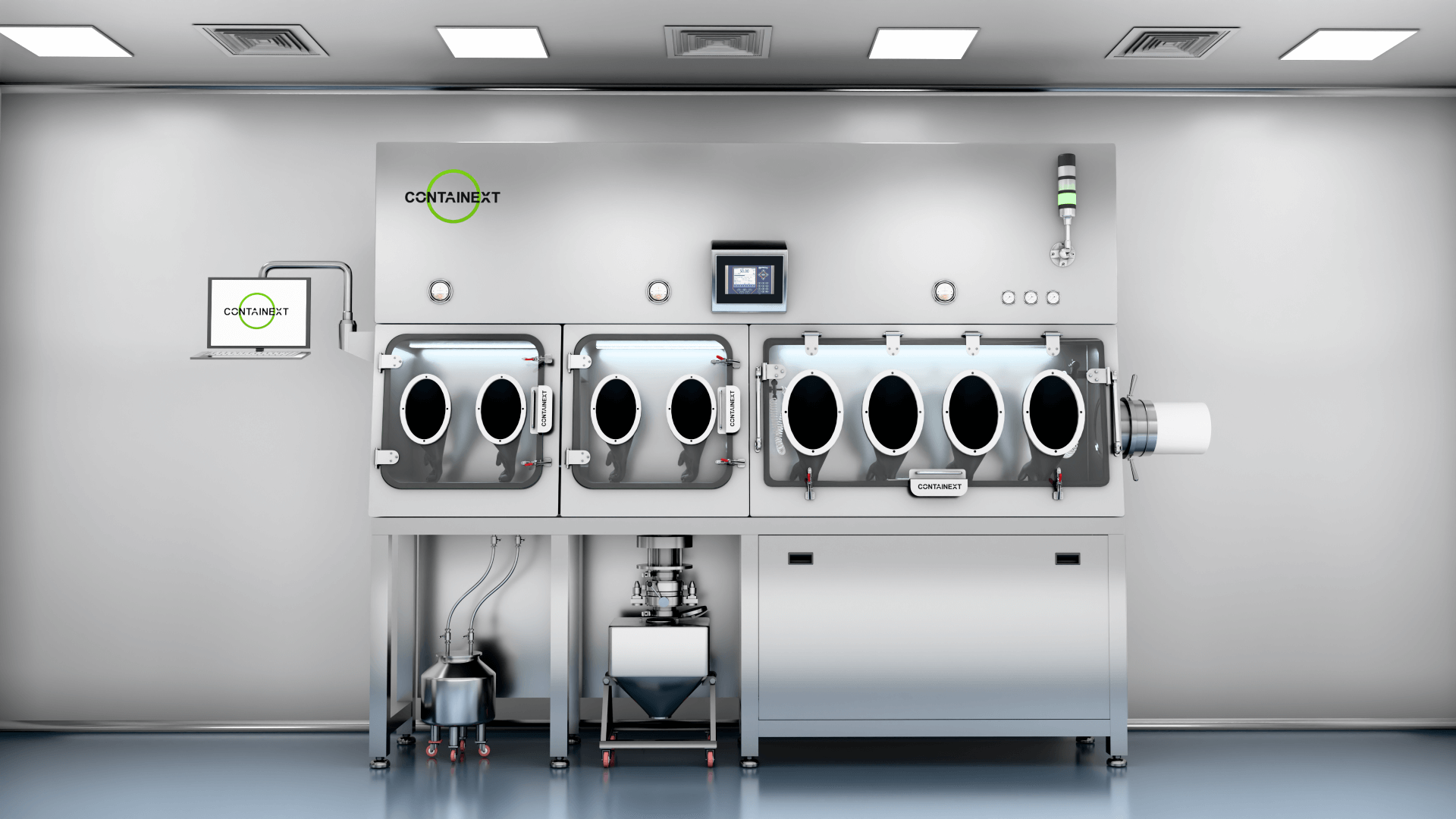

Advanced Compression and Capsule Filling Isolator

The Compression and Capsule Filling Isolator is a high-performance containment system tailored for pharmaceutical manufacturing. It ensures sterile environments for tablet compression and capsule filling, minimizing contamination risks. With modular designs, integration options, and compliance with regulatory standards, it enhances safety and efficiency in production

Sterile and Efficient Design

Advanced Compression and Capsule Filling Isolator

The Compression and Capsule Filling Isolator is a high-performance containment system tailored for pharmaceutical manufacturing. It ensures sterile environments for tablet compression and capsule filling, minimizing contamination risks. With modular designs, integration options, and compliance with regulatory standards, it enhances safety and efficiency in production

Specifications

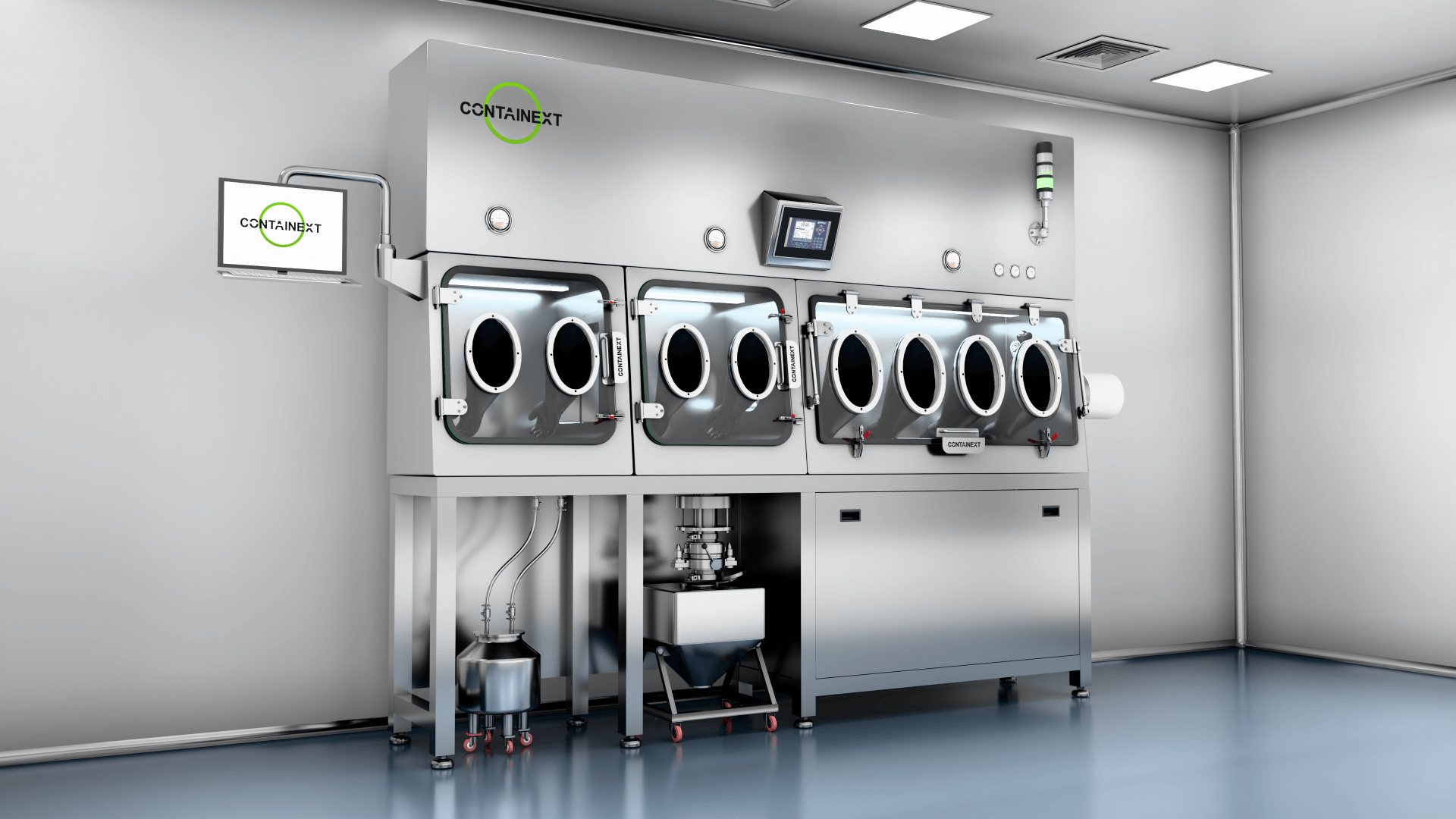

Modular Design

Allows seamless integration of compression and capsule filling machines, offering flexibility for customized configurations and optimized production environments.

High Containment

Ensures operator safety and product integrity by maintaining sterile conditions, preventing cross-contamination, and meeting OEL 5 containment levels.

Integrated Systems

Supports integration with line machines and tools, enhancing workflow efficiency and reducing downtime in pharmaceutical manufacturing.

Flexible Construction

Available in rigid or flexible designs, tailored to diverse operational requirements, ensuring adaptability for various production scales and needs.

Negative Flow

Features turbulent negative pressure airflow, designed for superior containment and protection against hazardous particles during operations.

Regulatory Compliance

Built to meet GMP, cGMP, ISO 10648-2, and ISO 14644-7 standards, ensuring quality and regulatory adherence for global pharmaceutical manufacturing

Contact Details

Germany (corporate office)

India (factory- headoffice)

India (factory- headoffice)