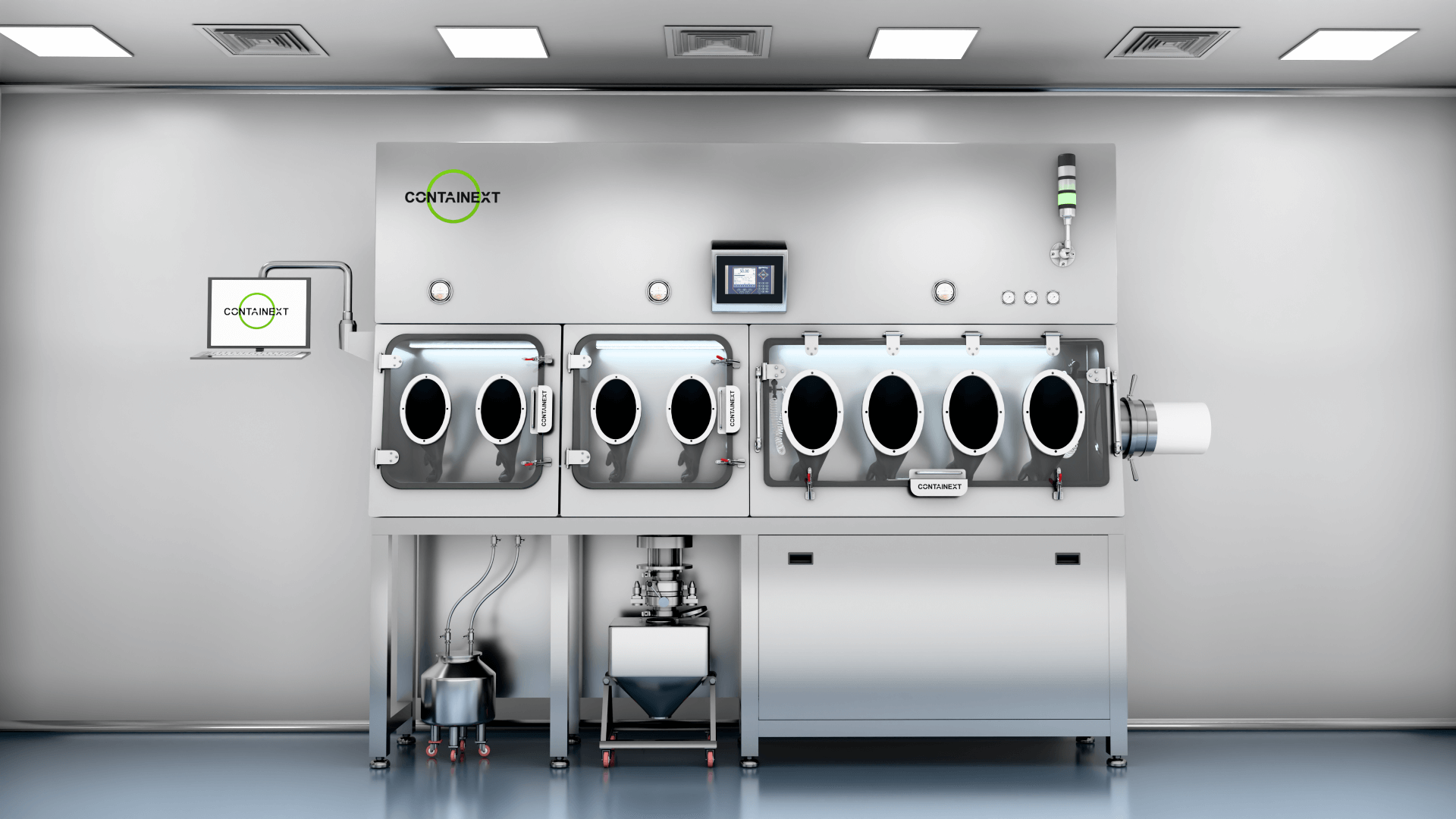

Customized Granulation Systems

Advanced Contained Granulation Isolator Solutions

The Contained Granulation Isolator offers negative pressure containment for safe handling of granulation processes in pharmaceutical manufacturing. It features customizable options, including safe-change filters and integrated systems for material handling. Designed for enhanced safety and efficiency, it ensures compliance with OEL standards and optimizes drug processing with innovative technologies.

Specifications

Negative Pressure

Ensures containment with negative pressure during granulation, maintaining safety and preventing contamination in the pharmaceutical manufacturing process.

Customizable Design

The isolator offers flexibility in design to meet specific operational needs, ensuring efficiency and functionality for various granulation processes.

HEPA Filters

Equipped with high-efficiency particulate air (HEPA) filters for effective contamination control and ensuring a sterile environment during production.

Touchscreen Interface

Features an intuitive 12" color touchscreen interface for easy operation and monitoring, enhancing control over the granulation process.

Safe Glove Ports

Designed with safe change glove ports to allow operators to handle materials without direct contact, maintaining a contamination-free environment.

Modular Construction

The modular design allows for easy integration with other equipment, providing scalability and adaptability to changing production requirements